In the realm of prosthodontics, final impression material for complete dentures holds paramount importance. This article delves into the intricacies of these materials, exploring their characteristics, impression techniques, tray selection, and post-impression handling, providing a comprehensive understanding for dental professionals.

Final impression materials play a pivotal role in capturing the intricate details of the edentulous arch, ensuring the fabrication of well-fitting and functional dentures. Understanding their properties and proper handling techniques is essential for achieving optimal clinical outcomes.

Final Impression Materials for Complete Dentures

Final impression materials play a crucial role in the fabrication of complete dentures, ensuring accurate reproduction of the oral tissues for optimal fit and retention. These materials must possess specific physical and chemical properties to effectively capture the intricate details of the edentulous ridge and surrounding structures.

Material Characteristics

Essential properties of final impression materials include:

- Dimensional stability:Minimal dimensional change after setting to preserve impression accuracy.

- Accuracy:Ability to accurately capture the details of the oral tissues.

- Viscosity:Appropriate flowability to adapt to the oral tissues without excessive displacement.

- Setting time:Sufficient working time to allow proper placement and manipulation, followed by adequate setting time to ensure stability.

- Biocompatibility:Non-toxic and non-irritating to oral tissues.

Commonly used final impression materials include:

- Polyether:High dimensional stability, accuracy, and biocompatibility; relatively expensive.

- Addition silicone:Good dimensional stability and accuracy, hydrophilic; requires precise mixing ratio.

- Condensation silicone:Less expensive than polyether and addition silicone; may exhibit some dimensional instability.

Impression Techniques

Various techniques are employed for taking final impressions for complete dentures:

- Single-step impression:Taking a single impression using a single material, typically a heavy-bodied material.

- Two-step impression:Using a light-bodied material for border molding followed by a heavy-bodied material for the final impression.

- Wash technique:Applying a thin layer of low-viscosity material over a previously taken impression to improve accuracy.

The choice of technique depends on factors such as the clinical situation, operator preference, and desired level of accuracy.

Tray Selection and Design

![]()

Appropriate tray selection is crucial for successful final impressions:

- Size and shape:Should closely match the patient’s edentulous ridge to provide adequate support and prevent overextension.

- Material:Perforated or fenestrated trays allow for escape of excess impression material.

- Handles:Facilitate easy insertion and removal.

Customizing trays may involve:

- Trimming:Removing excess material to ensure proper fit.

- Adding extensions:Creating additional support for unstable ridges.

- Modifying handles:Adjusting the angle or length for optimal manipulation.

Impression Materials

Final impression materials vary in their properties:

- Viscosity:Heavy-bodied materials are used for the final impression, while light-bodied materials are suitable for border molding.

- Setting time:Varies from quick-setting to slow-setting materials; faster setting times may be preferred for patients with limited tolerance.

- Accuracy:Some materials exhibit higher accuracy than others, depending on their dimensional stability and ability to capture fine details.

The choice of impression material should consider the clinical situation, desired accuracy, and patient tolerance.

Border Molding

Border molding is essential for creating an accurate and well-fitting denture:

- Importance:Captures the peripheral contours of the edentulous ridge, ensuring proper seal and retention.

- Techniques:Using a light-bodied material, the periphery of the tray is carefully adapted to the tissues.

- Materials:Light-bodied polyether, addition silicone, or condensation silicone are commonly used for border molding.

Proper border molding significantly enhances the accuracy and retention of the final denture.

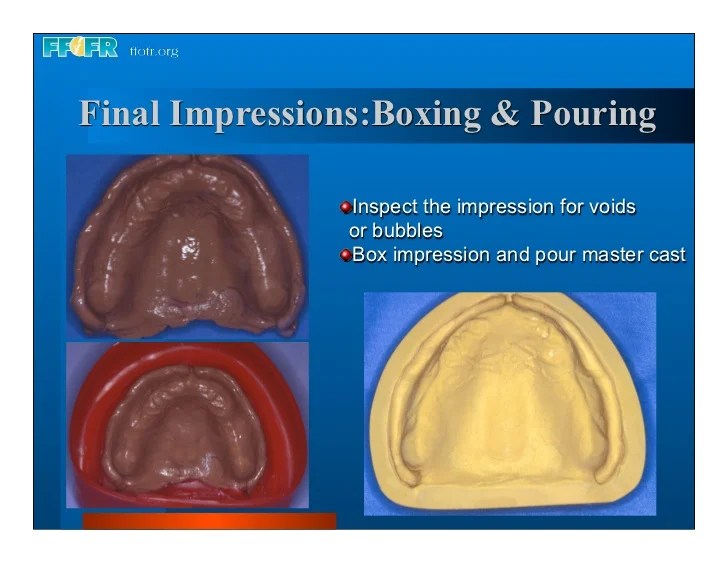

Post-Impression Handling: Final Impression Material For Complete Denture

Proper handling of final impressions is crucial to preserve their accuracy:

- Disinfection:Impressions should be disinfected to prevent cross-contamination.

- Storage:Store impressions in a humid environment to prevent dehydration and dimensional changes.

- Transportation:Use appropriate containers and padding to protect impressions during transportation.

- Timeliness:Casts should be poured as soon as possible to minimize dimensional alterations.

Timely and appropriate handling ensures the integrity of the impression, leading to accurate and successful denture fabrication.

Clarifying Questions

What are the key properties of final impression materials?

Final impression materials should possess dimensional stability, accuracy, and appropriate viscosity to capture the intricate details of the edentulous arch.

How does the choice of impression technique impact the accuracy of the impression?

The choice of impression technique depends on factors such as the clinical situation and the type of impression material used. Proper technique selection is crucial for obtaining an accurate impression.

Why is border molding important in final impression procedures?

Border molding helps to create a precise and well-defined border for the denture, ensuring proper retention and preventing tissue irritation.